CHNGS Gongshun Electric attaches great importance to the Saudi Arabian market

1. Introduction

As the global energy landscape shifts toward cleaner sources and power systems become ever more intelligent, medium-voltage distribution equipment is being held to higher standards of safety, reliability, and digital capability. CHNGS—specializing in R&D, manufacturing, and delivery of 12 kV–40.5 kV class GIS, AIS switchgear, and integrated ring-main, feeder, and transformer cells—has leveraged deep industry experience, advanced technical platforms, and a robust service network to earn widespread recognition in both domestic and overseas markets (notably in the Middle East and Southeast Asia). This article analyzes CHNGS’s six key competitive advantages in the MV arena, offering reference points for customers’ selection, design, and procurement efforts.

2. Company Profile & Development History CHNGS

-

Founding & Positioning

Established in 20XX, CHNGS Electric has been wholly focused on power-equipment manufacturing. Its core product lines cover 12 kV–40.5 kV GIS/AIS switchgear, multifunctional ring-main units, feeder and transformer cells, and turnkey substation solutions serving diesel, wind, solar, rail transit, and industrial distribution applications. -

Production & Market Expansion

-

Domestic: Early on, CHNGS passed IEC 62271 and IEC 61439 type tests, securing orders from State Grid Corporation of China, multiple provincial utilities, and major industrial users.

-

International: Since 2025, CHNGS has set up branches or partner factories in Saudi Arabia, Nepal, and Vietnam, delivering localized manufacturing and support for ring-main distribution, PV inverters, and municipal substation projects.

-

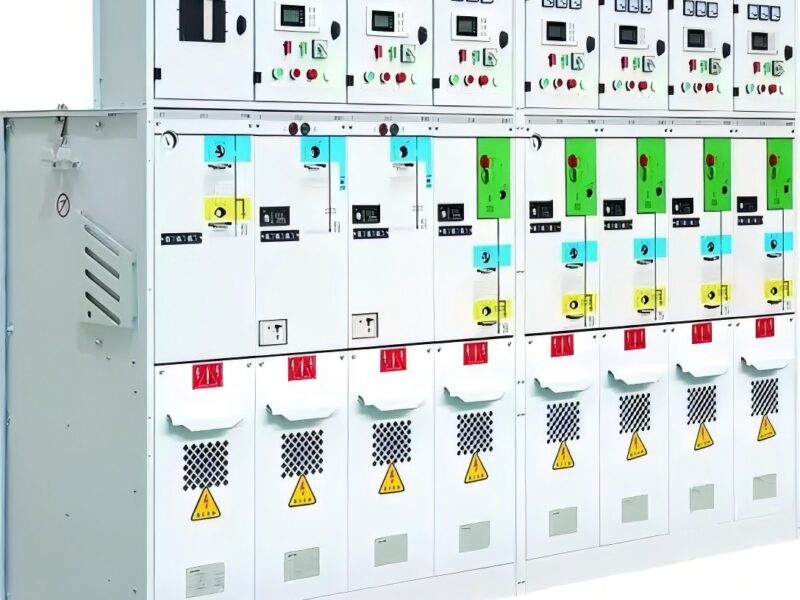

CHNGS MV Switchgear

-

3. R&D & Innovation Capability CHNGS

-

Comprehensive R&D Infrastructure

-

National-level Platforms: Hosts a provincial engineering technology research center and a postdoctoral research station, complete with a high-voltage lab, SF₆ gas analysis lab, and intelligent manufacturing workshop.

-

Academia-Industry Collaboration: Partners with leading universities and institutes to crack core challenges in “high-insulation composite materials,” “SF₆-free microclimate insulation,” and “integrated live-monitoring and fault-diagnosis.”

-

-

Patents & Standards Leadership

-

Over 50 granted invention patents and 80+ utility models.

-

Actively participates in drafting and revising IEC and GB/T standards, with CHNGS experts serving on multiple international committees—ensuring its products stay at the cutting edge.

-

-

Digital & Intelligent Solutions

-

Proprietary “online SF₆ monitoring system,” “bus-current/temperature integrated sensor module,” and “cloud-based O&M big-data platform” move maintenance from reactive to predictive, reducing outages and lifecycle costs.

-

CHNGS GSM6-1224-Air-insulated-RMUFixed-Type

-

4. Product Portfolio & Differentiated Advantages CHNGS

4.1 GIS/AIS Medium-Voltage Series

-

GIS (Gas-Insulated Switchgear)

-

Ultra-compact: <0.35 m² footprint per unit.

-

High performance: Rated up to 40.5 kV, 630–4,000 A, 25–40 kA/1 s short-time withstand, all type-tested to IEC.

-

Eco-friendly: SF₆-alternative mixed gases with lower GWP.

-

-

AIS (Air-Insulated Switchgear)

-

Robust in corrosive climates: IP54–IP65 versions survive salt-fog and industrial pollution.

-

Flexible topology: easily field-configurable for ring, feeder, and bus-section schemes.

-

CHNGS

-

4.2 Ring-Main & Feeder Units

-

Modular, pre-assembled ring-main units with built-in circuit breakers, load-break switches, earthing switches, and CTs—ideal for unmanned mini-environment sites.

-

Feeder units rated up to 2,500 A with 31.5 kA/1 s withstand, optionally integrating capacitor switching or harmonic mitigation.

4.3 Transformer Cells

-

Support 33 kV→0.4/0.231 kV transformers with dual-blade isolators plus switch combinations for enhanced protection and simplified maintenance.

4.4 Integrated Substation Solutions

-

Turnkey delivery: from primary MV equipment through secondary control, LV distribution, to SCADA/PLC.

-

Full-scope design—cabinets, foundations, grounding, lightning arresters, and control/monitoring systems—cutting site work and commissioning time by over 30%.

5. Quality Assurance & Certification

-

Rigorous QMS

-

ISO 9001 (Quality), ISO 14001 (Environment), ISO 45001 (OH&S) fully implemented.

-

Critical components (busbars, SF₆ seals, breaker mechanisms, CT/VT) sourced from top global vendors with dual-sourcing to ensure supply security.

-

-

Third-Party Type & Routine Tests

-

All products type-tested by UL, KEMA, CQC, etc.

-

Routine tests include dielectric withstand, mechanical endurance, gas-tightness, temperature-rise, protection-relay functionality, and EMC compliance.

-

-

Factory & Site Acceptance

-

FAT with on-site witness and full data reporting.

-

SAT coordinated with local utilities, achieving 100% first-pass energization success.

-

6. Customized Solution Capability

-

In-Depth Requirements Analysis

-

Tailored feasibility studies for special needs (explosion-proof for petrochemical, seismic-rated for rail, frequent switching for solar farms), producing detailed “MV Electrical Solutions” plans.

-

-

Modular & Flexible Design

-

Reconfigurable busbars and plug-in protection units enable rapid expansion and function upgrades.

-

Native support for Modbus RTU, Profibus DP, IEC 61850—eases integration into DCS/EMS networks.

-

-

Localized Engineering

-

On-site engineers in Saudi Arabia, Nepal, etc., customize cabinet finish, labeling, accessories, and installation procedures per local grid codes (TN-S, TT, IT earthing).

-

7. Manufacturing & Delivery Capability

-

Smart Factory & Capacity

-

Automated SF₆ filling and leak-test lines.

-

MES-driven traceability of raw materials, process parameters, test records, and operator credentials—ensuring full process transparency.

-

-

Parallel Assembly & Testing

-

Cabinet assembly, secondary wiring, and SCADA interface tests run concurrently—shortening lead times by 15–20%.

-

Overseas branch warehouses provide local fabrication, just-in-time joint inspection, and delivery.

-

-

Logistics & On-Site Handover

-

Detachable busbar segments and foldable supports for multimodal shipping.

-

Specialized packaging for shock, moisture, and sand-storm resistance—contracts specify insurance and handling protocols.

-

8. Service Network & After-Sales Support

-

Global Service Centers

-

Five regionals in Middle East, Southeast Asia, South America; 24/7 technical hotline linked to remote-monitoring platform for round-the-clock response.

-

-

Spares & Maintenance

-

Local stocks of breakers, protection relays, sensors, and busbar modules—48 h spare-part delivery.

-

Standard and tailored maintenance agreements, with monthly/quarterly online inspections and performance reports.

-

-

Training & Knowledge Transfer

-

Regular MV-electrical training courses covering selection, installation, commissioning, fault analysis, and digital O&M.

-

Certified-operator programs to ensure safe, compliant site work.

-

9. Industry Case Studies & Market Impact

-

Domestic Flagship Projects

-

SGCC Jiangsu 500 kV GIS Package: Supplied 80×36 kV GIS units, >3 years operation with zero failures.

-

CRRC Changchun Rail Transit: 50×24 kV GIS sets meeting seismic Class 9.0 standards.

-

-

International Deployments

-

Saudi Aramco PV Plant: Delivered 2×36 kV feeder units, 24×ring-main units, transformer cells, and turnkey substation—FAT/SAT passed at first attempt.

-

Pokhara Hydropower, Nepal: Supplied 12×33 kV GIS with SCADA integration and real-time monitoring—enhancing grid intelligence.

-

-

Customer Feedback

-

Warranty-period repair rate <0.2%; recognized as “Outstanding Supplier” and “Best EPC Partner.”

-

Average satisfaction score 4.8/5, with particular praise for response speed and remote diagnostics.

-

10. Sustainability & Corporate Responsibility

-

Green Manufacturing

-

“Zero-emission workshop” initiatives, optimized SF₆ recycling and emission-control processes—significantly reduced product carbon footprint.

-

Annual Product Life-Cycle Assessments (LCA) with published sustainability reports.

-

-

Safety & Community Outreach

-

HSE management yields zero onsite incidents.

-

Conducts local community electrical-safety training to raise awareness among operators and residents.

-

11. Future Outlook

Aligned with “carbon peak” and “carbon neutrality” goals, CHNGS will:

-

Accelerate SF₆-alternative Technologies: Polymer composites and micro-gas mixtures nearing commercialization.

-

Advance Digital Grids: Deploy AI and edge-computing for “digital twins” and self-healing ring networks.

-

Expand Modular Microgrids: Flexible MV solutions for DER and DC distribution.

-

Deepen Global Services: Establish two more regional operations centers in Saudi Arabia and Southeast Asia to boost delivery and O&M efficiency.

12. Conclusion

With its rich technical heritage, end-to-end product line, and worldwide service footprint, CHNGS has emerged as a frontrunner in the medium-voltage electrical sector. Looking ahead, the company remains customer-focused and innovation-driven, committed to delivering high-reliability, high-efficiency, low-carbon, and fully smart solutions that propel the global power industry toward sustained, high-quality growth.