The Environmental Impact and Operational Efficiency of Dry-Type Transformers

Dry-type transformers are revolutionizing the energy sector by providing safer and more cost-effective alternatives to oil-filled transformers. This essay aims to highlight the importance of understanding the benefits and applications of these transformers for environmentalists, energy professionals, and engineers.

In this discussion, we will explore the distinctive features of dry-type transformers, their environmental advantages, and how they contribute to operational efficiency.

What is a Dry-Type Transformer?

The primary distinction between dry-type and oil-filled transformers lies in their use of insulation. Dry-type transformers utilize air or other non-liquid materials instead of oil for insulation, making them safer and more environmentally friendly. They are suitable for both indoor and outdoor use, particularly in areas with stringent safety and environmental regulations.

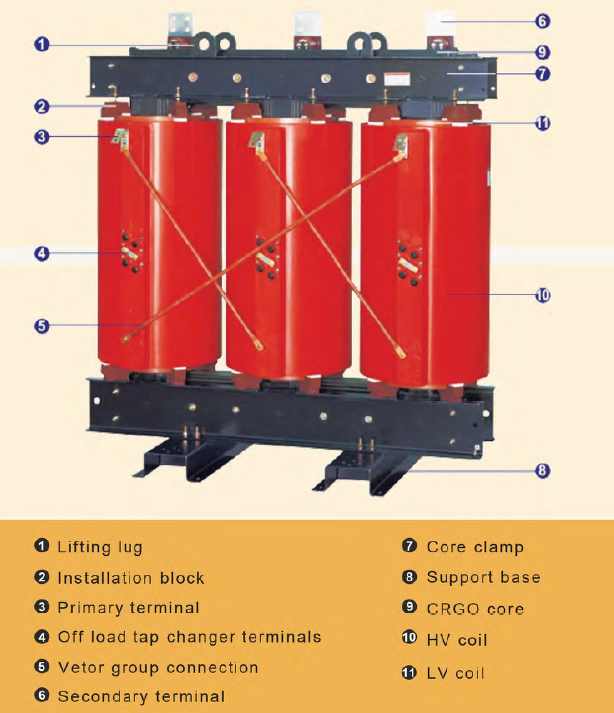

1:SC(B) Series Epoxy Resin Dry-Type Transformer

Structure and Benefits:

The SC(B) series transformers are designed specifically for modern electrical supply networks. They incorporate superior materials and advanced manufacturing techniques to ensure low loss and high efficiency.

- Core Construction: High permeability silicon steel is used, resulting in low no-load loss and noise.

- Winding Materials: Low-voltage windings use copper foil for insulation, providing moisture resistance and excellent electrical performance. High-voltage windings employ a multi-layer wire winding for superior electrical performance.

- Accessories: An isolation fan or housing enhances the transformer’s overload capacity and electrical integrity.

Environmental Impact:

These transformers are oil-free, reducing the risk of fire outbreaks and oil leaks. Their rigid components can be recycled, minimizing environmental impact.

SCBH15 Series Amorphous Alloy Dry-Type Transformer

Technical Specifications:

The SCBH15 series transformers are characterized by an amorphous alloy core structure that significantly reduces energy loss. They are ideal for applications in high-rise buildings, commercial developments, and other locations with strict safety concerns.

- Rated Voltage: Available in various voltage ranges to meet diverse requirements.

- No-Load and On-Load Loss: These transformers have low no-load and on-load losses, contributing to energy savings.

- Customizable: Specifications, capacity, and size can be tailored to meet specific needs.

2:Advantages:

- Energy Efficiency: No-load losses are reduced by one-third compared to conventional transformers.

- Safety: Flame-retardant and heat-resistant materials with excellent moisture-resistant properties.

- Maintenance-Free: Easy to install and operate with low running costs.

5G(8) 10 Insulated Three-Phase Dry-Type Transformer

3:Design and Construction:

This transformer offers high efficiency and reliability, suitable for various industrial power applications.

- Core Material: High permeability silicon steel sheets minimize loss and noise.

- Winding Structure: High-voltage coils use Nomex insulation, providing mechanical strength and heat dissipation.

- Thermal Shock Resistance: Capable of operating under extreme conditions without performance degradation.

4:Operational Assurance:

Designed to work efficiently and reliably in harsh environments that can impair the functionality of other hardware devices.

- Enclosure Options: Available in IP 20 and IP 23 protection levels.

- Temperature Control: Integrated with fast PT thermistors and RS232/485 interfacing capabilities for continuous monitoring.

- Cooling Methods: Natural and forced air cooling options are available.

Environmental Benefits of Dry-Type Transformers

Safety and Sustainability:

Dry-type transformers do not require oil, eliminating the risks associated with oil spills and fire accidents. They are made of recyclable parts, reducing waste.

- No Harmful Gases: Unlike oil-filled transformers, dry-type transformers do not emit harmful gases during cooling.

- Lower Noise Levels: The technology minimizes sound pollution, making it suitable for residential areas.

- Reduced Maintenance: Minimal maintenance requirements reduce the total cost of ownership.

Applications of Dry-Type Transformers

Industrial and Commercial Use:

Dry-type transformers are superior to oil-filled transformers in terms of gas emissions. They are ideal for:

- High-Rise Buildings: Enhancing productivity and safety in compact areas.

- Commercial Centers: Ensuring reliable power supply with minimal environmental impact.

- Airports and Subways: Improving safety in high-risk areas.

Special Environments:

These transformers are also suitable for harsh environments such as:

- Nuclear Power Plants: Meeting the high fire resistance requirements for reliability.

- Metallurgical Operations: Withstanding extreme climatic conditions.

- Petrochemical Industries: Using non-toxic and flame-retardant materials to protect people and the environment.

Intelligent Transformer Solutions: Real-Time Monitoring

Dry-type transformers can be equipped with real-time monitoring systems to ensure optimal performance and prevent potential issues.

In conclusion, dry-type transformers offer numerous environmental and operational benefits, making them an ideal choice for various applications. As technology advances, they will play an increasingly critical role in building sustainable and efficient energy networks.

Very detailed introduction. Thanks for sharing your information.